The Methods Used To Make Haus Awnings

Get in Touch!

If you’re feeling inspired to improve your home with our range of blinds, shutters, screens and much more, you can get in touch with our expert design consultants. We’ll be happy to answer any questions you might have.

Contact UsShare this page

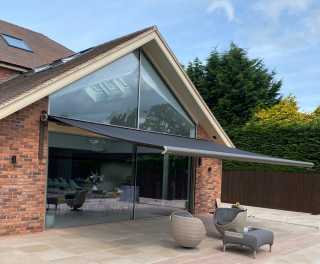

We love our range of Haus Awnings here at Appeal Home Shading. They’re the perfect addition to gardens and patios, and ideal for transforming your outdoor living space. Want a shaded area to relax in on those long summer evenings where you can read peacefully with no distractions but the birdsong? Or a perfect centrepiece for your next big social gathering? A Haus Awning is just the thing.

In the past couple of years, we’ve had many people enquiring about our range of awnings. One question that occasionally comes up is how they’re made. We should have expected this really; our customers are inquisitive and a lot of them are DIY enthusiasts who take great interest in how things are put together. So, we thought we’d write this brief explanation. This won’t cover everything in minute detail, but should hopefully satisfy your curiosity. Read on for an overview of the methods used to create a Haus Awning.

Creating A New Awning

To start off, we should probably point out how they’re not made. Yes, that might be unusual but bear with us, it’ll help to explain why we make certain choices. The average awning is made by a process known as die casting. If you’re not familiar with this term, it’s a construction method that involves forcing molten metal into a cavity while under high pressure. This results in the metal forming a specific shape as it cools and solidifies. It is useful and certainly has its merits, but it also has a couple of drawbacks, the biggest being that it can result in air bubbles getting trapped in the metal.

Our Haus Awnings are made using an alternative approach; drop forging. This involves dropping a weighted hammer onto pre-heated (but not molten) metal to shape it and is commonly used in the rail industry. Drop forging takes longer than die casting, but it also means that no air bubbles form in the liquid metal and get trapped when it hardens. The end result is a better-quality product that is stronger, more durable, and has a longer lifespan.

Fixing An Awning To A Wall

We use this method to create our awnings to the precise size and shape requested by the customer. It’s also worth mentioning that the string is similarly durable. You’ll commonly find steel strings in awning mechanisms, but this can degrade over time and need replacing. Ours is specially made to be longer-lasting and is stronger than Kevlar.

The big question though is how they’re attached to a wall. The standard approach is to bolt them in, but this can place strain on the brick and take away some of its inherent strength. As an alternative, we use a mechanical fixing and a chemical sealant that bonds the bolt to the wall. This means the brick itself isn’t compromised and the awning can be securely attached, without any loss of structural integrity.

These construction methods were chosen because they all extend the life of a Haus Awning. Once your new patio awning is up, you can trust it to outlive and outperform all its competitors. We pride ourselves on offering the best Awnings for UK homes and our Haus range is unbeatable.

If you’d like to know more, or have a project you want to get started on, why not get in touch? Book a free design consultation or download a brochure today. We can’t wait to hear from you.